Manufacturing press-hardened car body parts requires high-temperature processes – and this is exactly what the HyHeat project is addressing. The aim being to move to climate-friendly fuel gases and to actively improve the CO₂ balance.

Together with Forschungszentrum Jülich, we are developing a new process technology to help reduce emissions under the HyHeat research project. This project is part of the Helmholtz Hydrogen Cluster HC-H2.

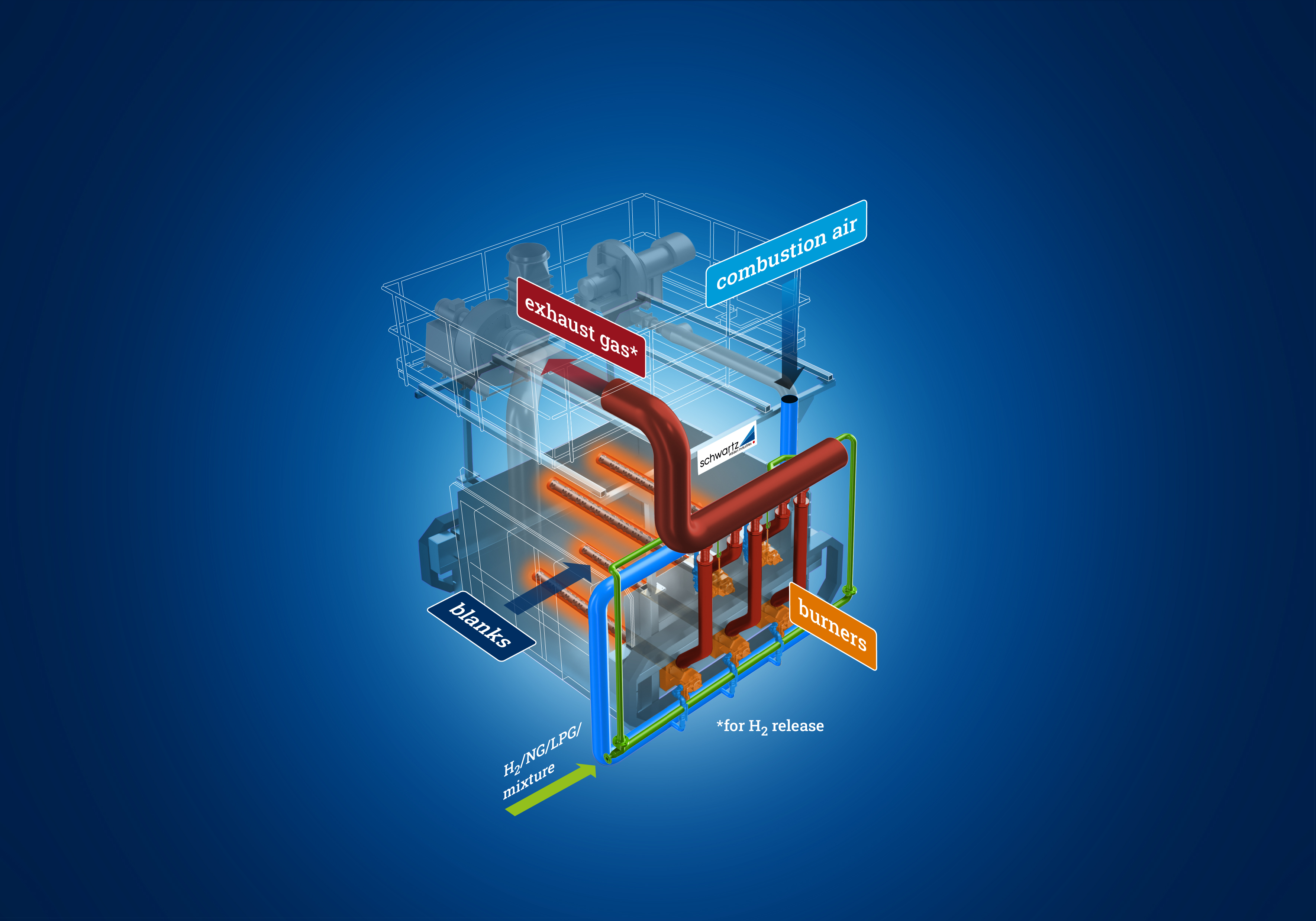

At its heart are innovative multi-fuel burners developed by our daughter Econova GmbH. These burners can run on hydrogen, natural gas and gas mixtures, combining high operational flexibility with constant power output.

In addition, waste heat from the equipment is used to release chemically absorbed hydrogen from a liquid organic hydrogen carrier – creating a clever link between process heat and hydrogen infrastructure.

HyHeat represents tomorrow’s climate-neutral production – a scalable, technology-neutral approach and one of the drivers of structural change in the Rhenish coal mining area.

The full article can be found here: HyHeat: Using Hydrogen for More Climate-Friendly Metal Processing

Foto © Forschungszentrum Jülich